NEWS HEADLINE

- ¡ yClick HerezGrout flow test of Mechanical Rebar connection system method for station MRT,column

- 2016/04/01

- ¡ yClick Herez Heat treatment

- 2015/07/13

- ¡ Fujibolt Corporate PR Video Eng

- 2015/06/03

- ¡ Official web site Renewal Open.

- 2015/06/01

Major earthquakes can occur anywhere in the world.

Rebar joints are one of the most important determinants of structural strength.

Japan has one of the world's highest occurrences of earthquakes. Fujibolt has always worked to provide safe and secure spaces. Major earthquakes such as the 1995 Great Hanshin Earthquake and the 2011 Great East Japan Earthquake remind us of the true value of such spaces. To further its mission of contributing to earthquake-resistant structures that can withstand such major earthquakes, Fujibolt established PT Fujibolt Indonesia in 2012, as the country also suffers from frequent earthquakes. Our products will continue to contribute to infrastructure development in Asia and around the world.

Fuji Boltfs gexcessivelyh robust and tough FD Grip helped protect the Nuclear Power Plant during the Great East Japan Earthquake of 2011 despite being located only 130km from the epicenter of the Magnitude 9.0 earthquake.

The Onagawa Nuclear Power Plant, which used Fuji Boltfs gexcessivelyh robust and tough FD Grip mechanical joints in its construction, remained almost completely undamaged during the Great East Japan Earthquake of 2011 despite being located only 130km from the epicenter of the Magnitude 9(M 9.0) earthquake, and was even able to serve as an emergency shelter for local residents. We believe that the buildings and structures that underpin our social infrastructure must be able to maintain their stability and safety even during unprecedented and unexpected events such as the Great East Japan Earthquake of 2011. That is why we designed our FD Grip mechanical joints to be gexcessivelyh robust and tough.

What Fujibolt Difference

As a specialized rebar mechanical splice manufacturer,

we are dedicated to the provision of earthquake-resistant structures.

Steel with High Levels of Strength and Ductility

Fujibolt uses carbon steel rather than cast iron to realize high levels of strength and ductility. Steel not only has excellent mechanical properties and toughness, but is also resistant to brittle fractures even when sudden, unexpected shocks, impacts or vibrations occur.

High Stiffness and Low Slippage

Using our precision screws and high-performance grout provides not only tensile strength but also high stiffness and low slippage in one-way tensile tests. Our products also maintain high stiffness and low slippage even in elastic and plastic cyclic tension-compression tests to comply with Japan's stringent requirements.

fujibolt

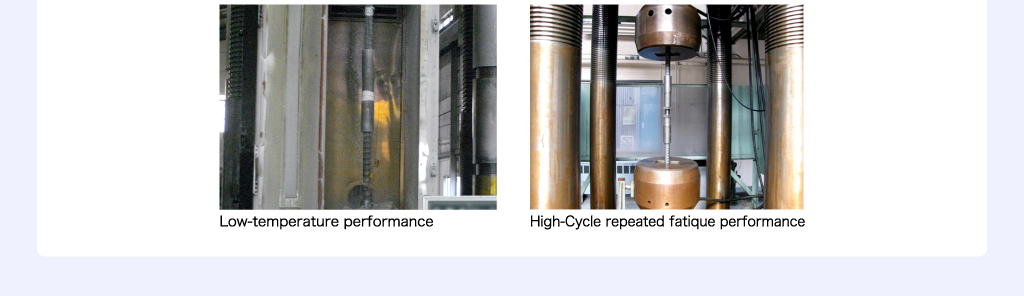

Performance That Withstands Harsh Environments

In addition to best-in-class joint performance, Fujibolt has ensured the performance of our rebar in harsh environments by carrying out low-temperature performance tests on LNG tanks and fatigue performance tests (high-cycle repeated fatigue tests) for railroads, roads and other structures that are subject to repeated variable loads.

Fujibolt is best-suited for the following types of users.

Project Owner

EWants to construct high-value, quality buildings or

infrastructure with superior earthquake resistance.

EWants to reduce life-cycling costs via structural durability.

EAppreciates Fujibolt's 30-year earthquake endurance track

record in Japan.

General Contractor

EWants mechanical splicing well beyond minimum requirements

that will easily pass any surprise onsite testing (as opposed

to just meetingthe needed minimum requirements).

EExpects conscientious service during the construction period,

such as speedy delivery and onsite guidance.

EBelieves that the cheapest rebar splicing is not necessarily

the best choice.

Structural Design Consultant

EWants to use reliable rebar splicing to achieve design strength.

ESeeks to emphasize the reliability of construction regardless

of the use of skilled craftsmen.

EWants to emphasize not only fundamental performance but other

types of performance, such as for fatigue and low-temperatures.

Rebar Manufacturer/Processer

ESeeks to create synergy by incorporating Fujibolt's high-quality rebar splicing into its own rebar products or rebar processing.

Trading Company

ELook for high-quality rebar splicing that meets local needs and is not deformation-dependent.

To Provide the World with Safe and Secure Spaces,

We would be very happy to discuss collaboration with regard to any of the following:

Sales agency targeting a specific country or countries

Strategic alliance with:

- Rebar manufacturers

- Rebar processing companies

- Precast concrete factories

Joint development of new products

![]()